VECTOR ETCH – (blue) should always be shown as 0.1pt blue (stroke only) Raster engraving can also be done double sided to decorate the front and back of your designs – but again this would in most cases almost double the cost of the job. We can do a few passes to get it deeper if required, but be aware this adds to the cost significantly though as engraving is an inherently slow process! Raster engraving is only really decorative and roughly 0.5mm in depth, although this varies and we cannot engrave to an exact specified depth. If you want a thinner cleaner line use the “vector etching” method (explained below). The thinnest black etching stroke in your file should be no less than 0.5pt-0.75pt. You can also use high quality JPG images but vector is always better. You can mask and cover black areas of your drawing because black artwork is essentially flattened as it’s sent to the cutter. Raster etching is created by the laser head going back and forth across the sheet like an inkjet printer would. We get good engraving results on all of the materials on our materials page, some show better than others, we have provided pictures of how our materials raster etch. When setting up your files with multiple pieces that need etching it is best to keep them all in the same area on the sheet and in horizontal rows where possible, this will etch quicker and therefore be cheaper for you. RASTER ETCH – (black) can be drawn as any combination of lines and strokes. Also double cut lines (one red line on top of another) will cut twice causing burning and you will be charged for the extra cut time too.

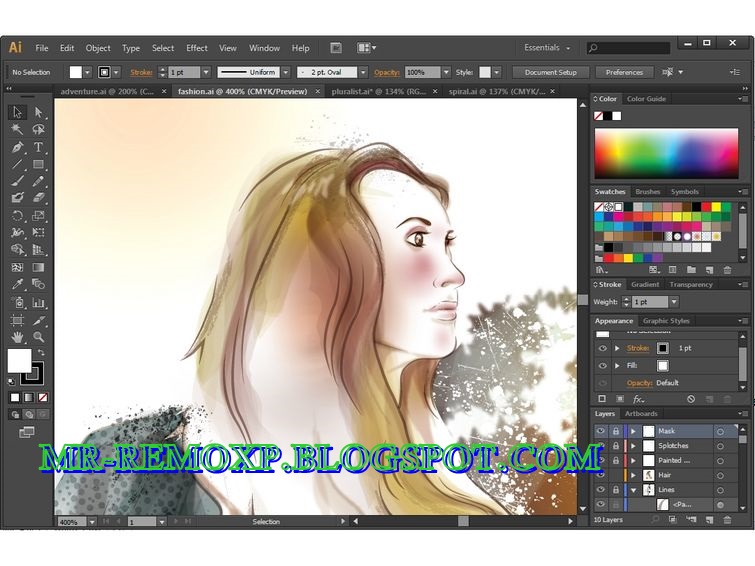

ADOBE ILLUSTRATOR TUTORIAL VECTORIZE JPB SOFTWARE

The laser cutting software will find and cut every red line in your file, if you overlap them, mask them or hide them under another object they will be found and cut.

It’s best to have all cut lines joined up so that the laser cutter follows the one single line and therefore cuts quicker, broken or segmented lines can result in longer cutting times. When cutting, intricate patterns take much longer to cut than simple shapes and straight lines are faster than tight curves or circles. We can cut materials from 0.5mm (paper/card) thick to 12mm thick (plywood). All of the materials listed can be cut, even the smallest of details. Our laser cutters can happily cut through a wide variety of materials as shown on our materials pages. When cutting, it cuts away approx 0.1mm of material on each side of the line. When the laser cuts it follows the red stroke lines in your file, straight down the middle of the line. CUT LINES – should always be shown as 0.1pt red stroke.

0 kommentar(er)

0 kommentar(er)